New avenues for cold forged parts

The exceptional is our standard

Where others turn back, we venture forward. As a flexible and creative problem solver in the field of cold mass forming technology, we break away from well-trodden routes to explore new avenues for helping our customers achieve efficient results.

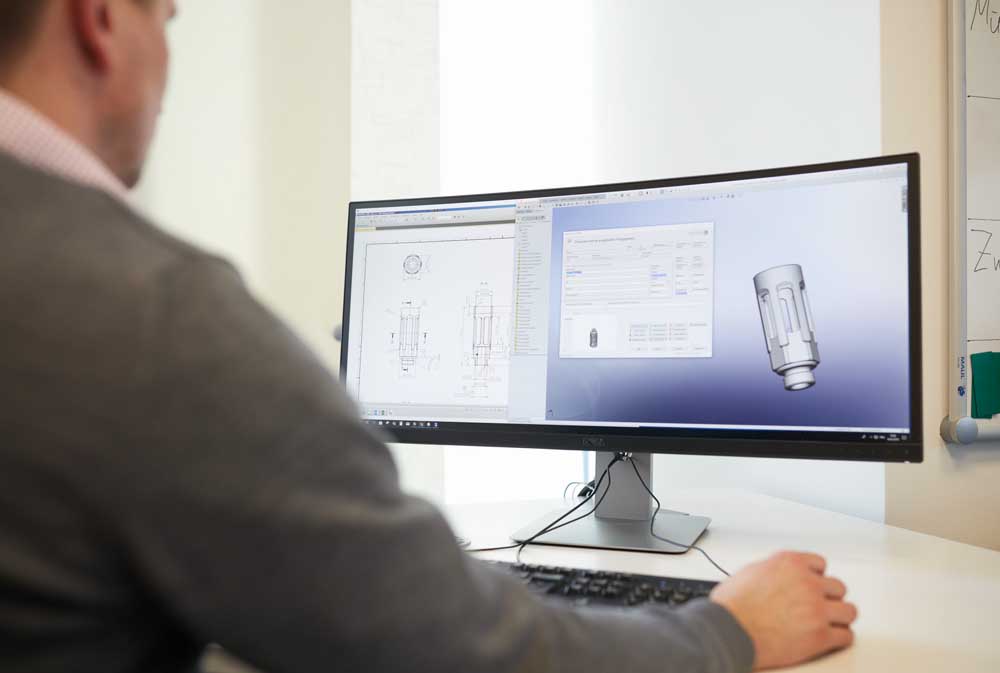

Components with challenging, asymmetric geometries? Unusual functional characteristics? Non-standard materials? Our exceptional depth of production coupled with our deep-seated expertise allows us to offer a broad spectrum of technologies in terms of both production facilities and materials. Alongside a wide range of machine types including vertical presses, Walter Schneider has its own toolmaking department and also extensive expertise in working with non-standard material such as stainless steel or nickel. All of which allows us to support and advise our customers right from the very start of the process, ideally as soon as the development phase. Geometry, material, machining steps – our designers know how to lay the groundwork for optimized component manufacture, and sometimes come up with solutions customers may find surprising. In terms of material consumption, production cost, quality and also functionality.

Advisory competence

The basis for optimum processes and efficient results

Flexibility

We possess the expertise and creativity to take new and totally individual directions

Vertical depth of production

Our large machine fleet and our own toolmaking department enable us to respond rapidly and provide the assurance of top quality

Material diversity

We offer a wide range of options and filter out the most suitable materials