Maximum manufacturing precision

Flawless quality

Our enormous depth of production not only means that we are outstandingly flexible. It is also a guarantee of the superb quality our customers have learned to appreciate. Maximum manufacturing precision aimed at “zero defects” is achieved with the aid of experienced specialist employees who receive regular further training and are fully integrated into the continuous improvement process. After all, quality planning and meticulous attention to all statistical key indicators are among the central aspects of every production process in our company.

The quality assurance experts at Walter Schneider use the very latest technologies and master a wide range of testing and measurement processes in our modern measurement lab: Simple, rapid contour scanning, professional measurement and testing of dimensional and position tolerances as well as 3D measurement tasks.

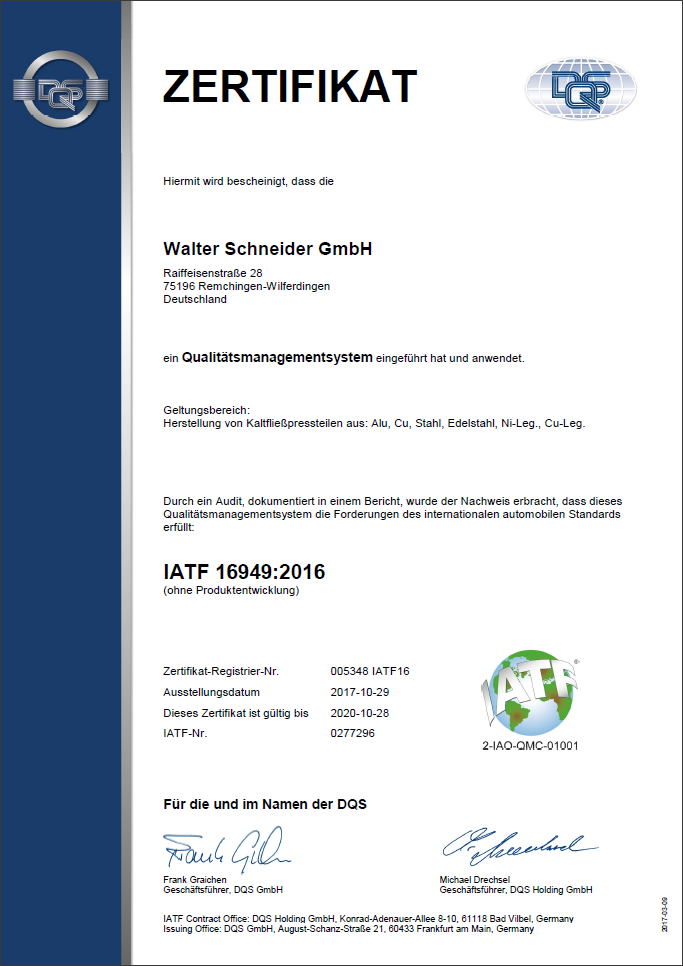

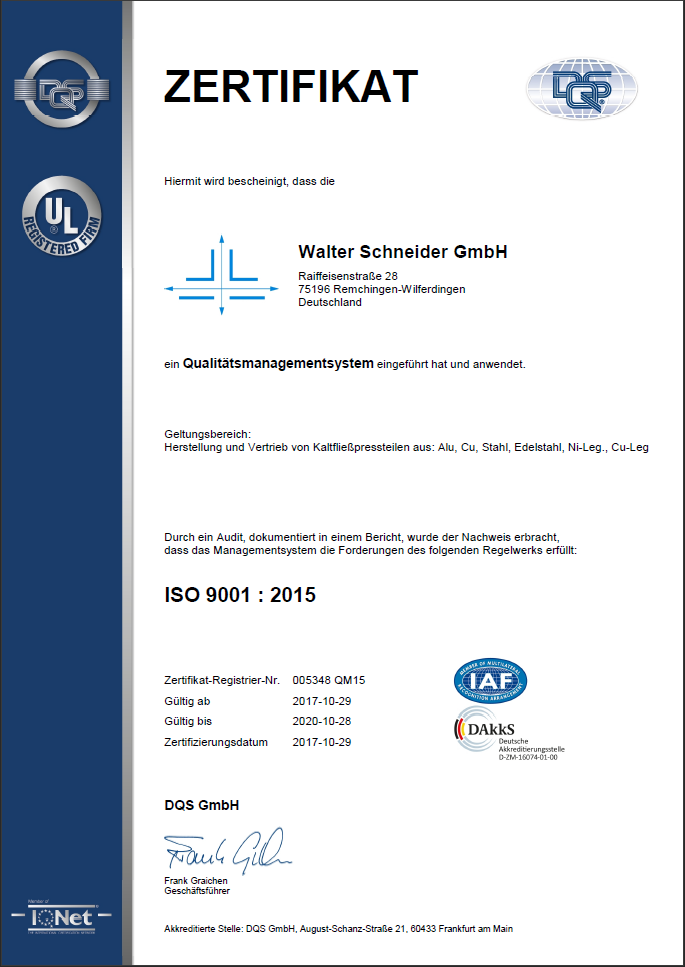

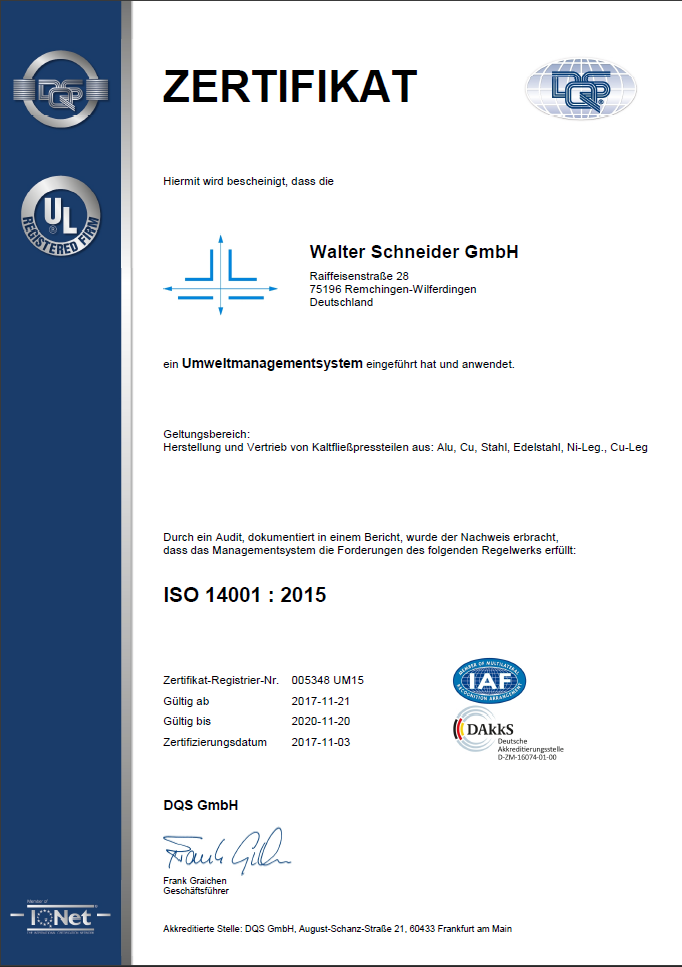

Certification

Certification to IATF 16949:2016 / ISO 9001:2015 & 14001:2015

The use of cold forged parts has become an indispensable element of modern production, for instance as components inside precision electronic products. The automation of cold forging processes has enabled this type of component to be produced at extremely high speeds, making them highly economical to manufacture - coupled with a high level of dimensional accuracy and surface quality. Typical cold forged parts include mass produced bolts, sleeves or gear shaft blanks.

Walter Schneider GmbH manufactures cold forged parts weighing anything from 1 to around 600 grams, primarily for use in the automotive industry, in mechanical engineering or the furniture fittings industry.