Extensive range of services

Development and production expertise

We make the complicated achievable, with expertise spanning the entire process chain. From the initial design to the ready-to-assemble component: bringing Walter Schneider on board means benefiting from comprehensive expertise, an extreme vertical depth of production and smooth, trouble-free processes.

Design

The stage plan:

Basis of the design

Stage plans from Walter Schneider enable economical production. Our decades of experience mean that we take the different framework conditions into account to achieve an efficient, practically rework-free production result using optimized forming steps.

The stage plan is configured so that

- the component is given the optimum desired geometry

- the material reaches all ends of the engraving as close to simultaneously as possible

- material flow is enabled at room temperature

- the lowest possible pressing forces are necessary

The stage plan forms the basis for:

- Tools

Our tools are designed to ensure optimum manufacturing of the pressed part using the planned facilities in line with the stage plan using the planned facilities - The forming machine

The forming press is defined in parallel with configuration of the stage plan. Data such as the compressive force, ejector force, working capacity, die mounting area and the force-displacement characteristic are key parameters governing the manufacture of components - Inspection of quality criteria

Surface, dimensional, position and shape tolerances are decisive for tool and die precision and the selection and number of required pressing operations - Economic considerations

To ensure the most economical solution for our customers, we define the most cost-effective sequence or combination of processes, and also check whether different production options would provide a higher quality or more economical solution than cold forging. Consequently, it is possible that the feasibility analysis favours the manufacture of blanks rather than cold forged parts on some occasions.

We produce all the designs for our press step sequences in-house. The design drawings form the basis for tool production in our own toolmaking department.

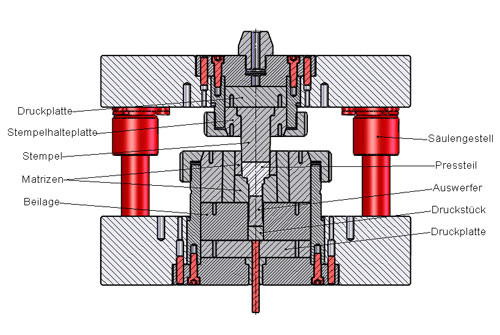

Toolmaking

The operational core of the company:

Our own in-house toolmaking department

The economic benefits of cold forging are only fully leveraged if the tool design envisages combining materials to achieve the maximum possible loading capacity and fatigue strength. The selection of hardness level is also a key criterion when it comes to a tool’s durability. Using wide-ranging different coating methods (application of a hard material layer by means of PVD or CVD treatment), it is possible to further optimize tool service life.

Achieving a long service life for tools calls for tool reinforcement. The tools are clamped together in such a way that they are pushed and pressed into each other with a certain allowance. Even where extreme degrees of deformation are called for, this means that high internal pressure levels can be controlled.

The toolmaking department represents Walter Schneider's operational nerve centre. Whatever our designers specify is implemented by our skilled specialist team. Milling, profile grinding, cylindrical grinding... Using these and other machining steps, complex precision tools are produced for our production department – with almost a 100% vertical depth of production and to the most stringent standards of durability and dimensional accuracy.

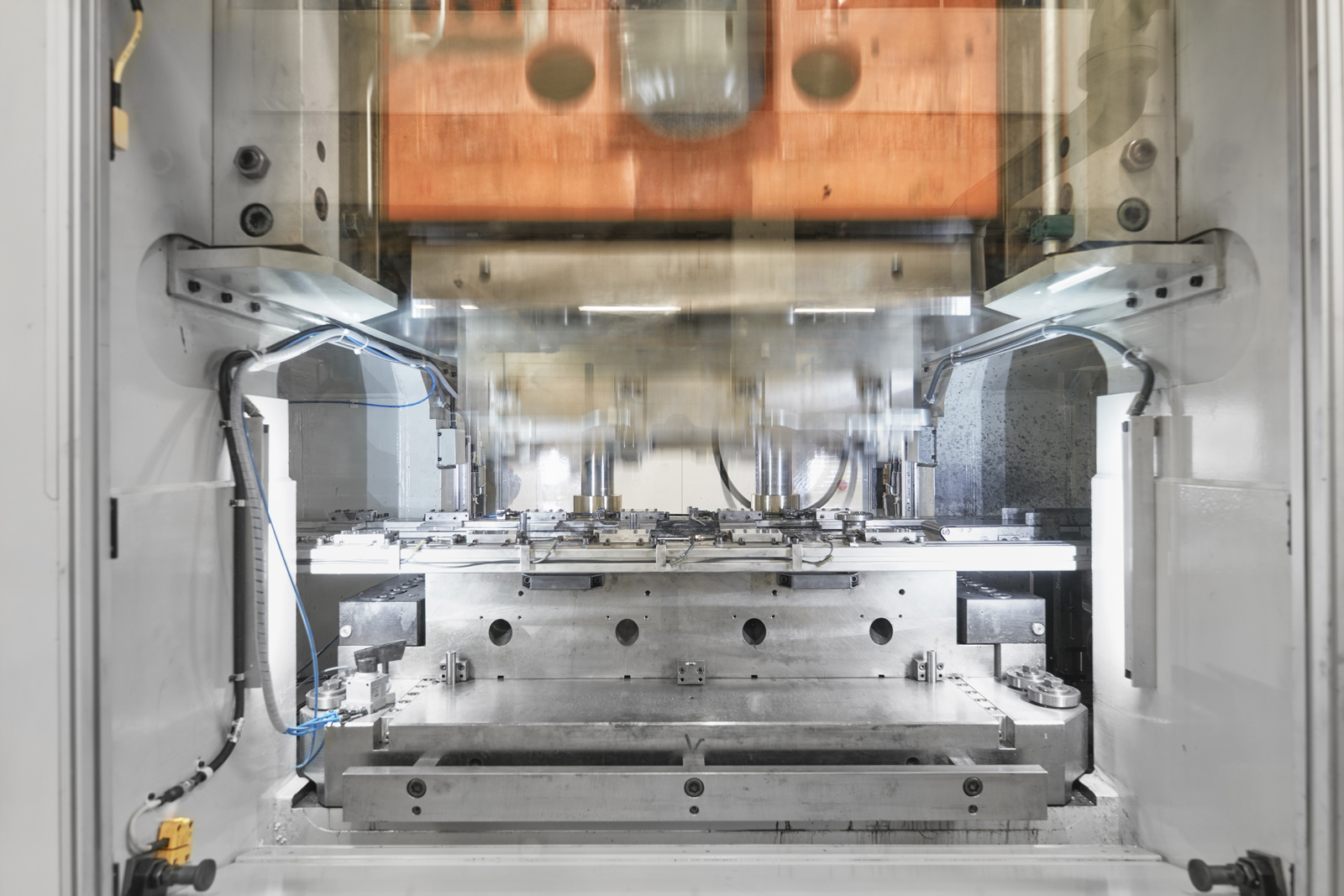

Production

The heart of the company:

Production

The pressing plant forms the heart of our company. Whether production tests, sample or mass production – Walter Schneider offers its customers an extensive array of production possibilities. From tool trials to series production, our designers prove their efficiency day to day in close and proven cooperation with the toolmaking department and the pressing plant.

Our pressing plant is manned by machine operators with a wealth of experience in operating presses with pressing forces between 80 and 630 tons. Their meticulous care and precision ensures the manufacture of optimum products to match individual customer mounting situations.

Part cleaning

Part cleaning:

A clean outcome

We are ideally placed at Walter Schneider when it comes to part cleaning too. For a wide range of materials such as stainless steel, aluminium or copper, our service ensures precisely the cleaning results our discerning customers expect.

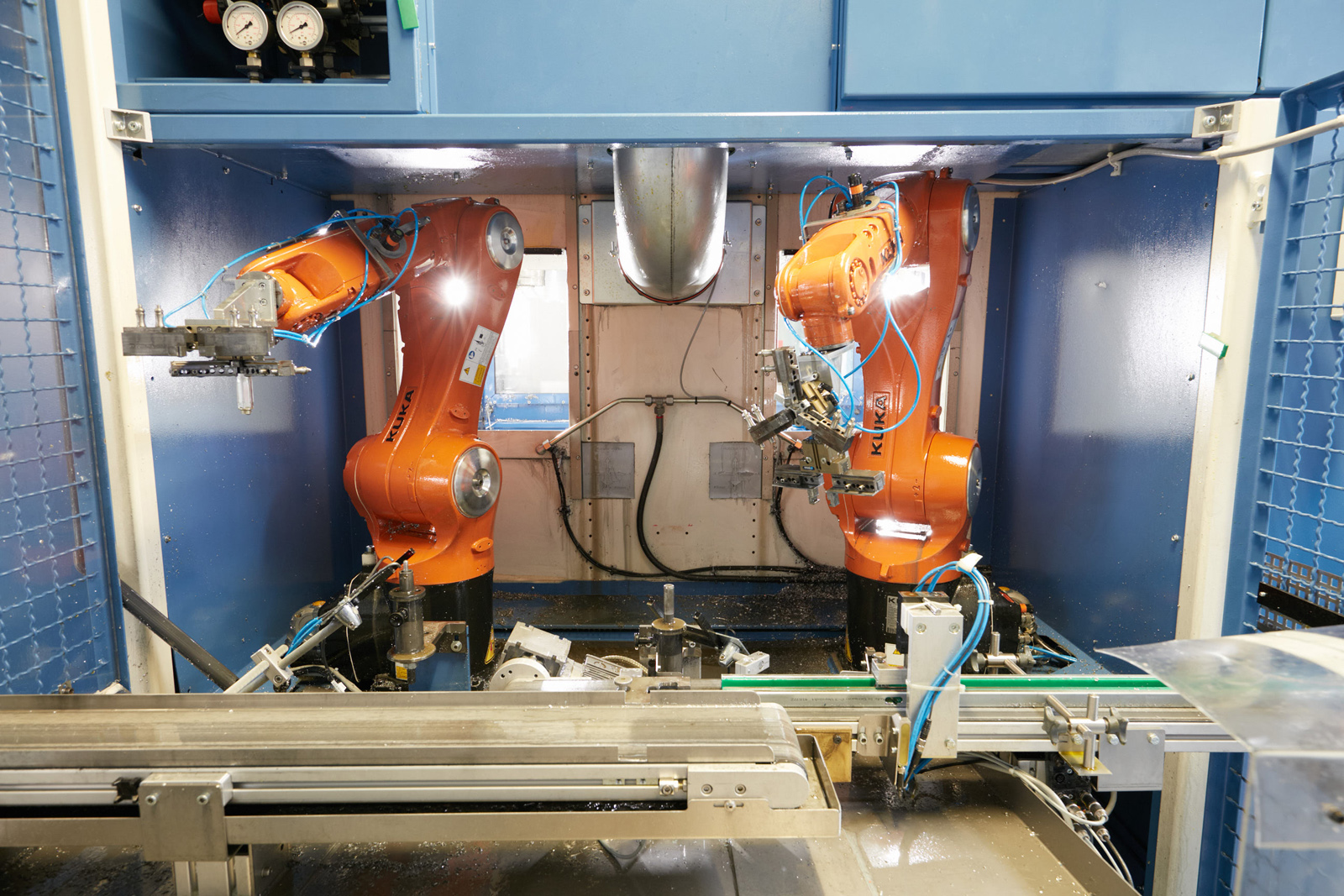

Rework

The finish:

Ready-to-install results

Our modern machine fleet – including robotics and assembly lines – allows us to offer our customers not only cold forging technology but also a broad spectrum of reworking options. The ideal addition to our vertical depth of production: If other machining steps than pressing technology are required to produce the desired finish, we can execute the following range of machining processes, for instance: Deburring, drilling, turning, milling, thread tapping, sawing and grinding. The result of these efficient finish processing stages are top-quality ready-to-install components - in a wide range of different shapes and tolerances.

1

1 2

2 3

3 4

4 5

5